Use this option to set general MJC configuration details such as how notional cost is calculated and the default job duration.

Refer to "Selecting a Company to Edit".

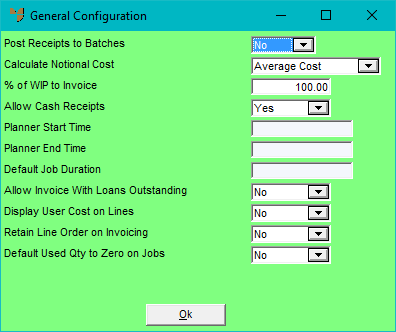

Micronet displays the MJC General Configuration screen.

|

|

Field |

Value |

|

|

Post Receipts to Batches |

Select Yes if you want Micronet to process receipts as a batch in MDS rather than job by job as the receipt is entered. This speeds up transaction processing during Goods Receipt in MDS. Select No if you want Micronet to process receipts as they are entered. |

|

|

Calculate Notional Cost |

Select the default cost and sell price of materials as they are added or transferred to jobs. Markups are also based on this cost. |

|

|

% of WIP to Invoice |

Enter the default percentage of Work in Progress to invoice. This is the percentage of WIP that you want transferred to Cost of Sales on invoicing a job. Micronet calculates and displays this amount during the creation of invoices and progress claims, but it can be overridden at invoicing time. For example, if you entered 80% and you had a job worth $100,000 with the amount completed to date at 50%, then when you created a progress claim, Micronet would calculate the amount of WIP to be taken up as:

The resulting invoice would show a profitability of $10,000 or 20%. |

|

|

Allow Cash Receipts |

Select how you want to deal with customer payments. Options are:

|

|

|

Planner Start Time |

If you are using Micronet Plant Maintenance, enter the default start time for a normal working day. |

|

|

Planner End Time |

If you are using Micronet Plant Maintenance, enter the default end time for a normal working day. |

|

|

Default Job Duration |

If you are using Micronet Plant Maintenance, enter the standard job duration for service jobs created for planned maintenance. |

|

|

Allow Invoice With Loans Outstanding |

If you are using Micronet Plant Maintenance, you can prevent jobs from being invoiced where loaned equipment has not been returned. Select Yes to allow invoicing of these jobs anyway, or select No to prevent these jobs from being invoiced. For more information about the Micronet Plant Maintenance system, refer to "PLANT + MAINTENANCE Menu: Micronet Plant Maintenance". |

|

|

Display User Cost on Lines |

Select the cost price you want displayed when users are adding items to service jobs:

In most cases, you would leave this set to No so that Micronet displays an item's average cost on the Add Items to Job screen. You would only set it to Yes if you create jobs and invoice them immediately. With this field set to No, average costs are updated and displayed on the Add Items to Job screen whenever an item line is edited. |

|

|

|

Warning If you select Yes in this field, be aware that the costs on the Add Items to Job screen will not be updated when costs in Micronet change. The first time a service job is saved, the costs entered will remain on the job until it is closed. Note that in the background, costs are still maintained correctly; they are just not displayed on the screen. Users will need to check costs before editing lines on any job. An example will illustrate the potential implications. When a user first creates a job and adds an item to it, the item's average cost is $15. However, their Show Cost on Inquiries field is set to Buy Price 1 and that price is $18. They add 2 units of the item to the job at $18 each so the total cost is $36. They save the job but keep it open for further changes. Several weeks later the user wants to add another 1 unit of the item to the job. When they go into the Add Items to Job screen, the Unit Cost still says $18 and they increase the quantity from 2 to 3 so the total cost is updated to 3 x $18 = $54. However, in the meantime, more stocks of the item have been received into the warehouse and the average cost of the item has increased to $17 and Buy Price 1 has increased to $20. So the user should have added the third item to the job at a cost of $20, not $18. |

|

|

Retain Line Order on Invoicing |

2.8 Feature By default, the item lines on a normal invoice for a service job, where the cost centres are set to itemised, are sorted by cost centre – see "Job Transaction Processing - File - Normal Invoice" in the Job Costing manual. This setting allows you to select the order in which you want the lines printed on the invoice. The options are:

|

|

|

Default Used Qty to Zero on Jobs |

Select how you want the quantity to default in the Qty Used field on the Add Items to Job screen on service jobs, manufactured jobs and internal jobs. By default this field is set to No. When users enter the Qty Req on a job line, Micronet checks the stock available. If sufficient stock is available, the Qty Used field defaults to the quantity required. If there is not enough stock available, the Qty Req field displays the quantity available and the Qty Order field displays any quantity that needs to be ordered to meet the requirement. If you set this field to Yes, when users enter the Qty Req on a job line, Micronet will ignore the stock level. The Qty Used will always default to zero and the quantity required will default in the Qty Ordered field. |

Micronet redisplays the Change Existing Company screen.